Concrete is the second largest consumed material in the U.S., and its production is responsible for 8% to 10% of carbon dioxide emissions. Civil engineers at Michigan State University have developed flexible concrete that is self-healing and produces heat, which could prove to be an environmentally friendly option for roads in terms of snow and ice removal.

“This could revolutionize the concrete industry and our infrastructure,” said Qingxu “Bill” Jin, an assistant professor in the College of Engineering. “This technology could also be a solution for underserved or rural communities with limited access to snow and ice removal options, providing a safer and more sustainable solution during winter months.”

Concrete is commonly used for roads and sidewalks because of its strength and durability. But the frequent freezing and thawing of water can create cracks, and snowplows cause surface damage resulting in costly road repairs and closures. During the winter, road and deicing salt is often used to melt the ice on roads and sidewalks, but the chloride in the salt is corrosive and damages the concrete. Also, any salt left over eventually ends up in the groundwater, causing environmental concerns.

“This concrete product can potentially be used as a protective layer over the pavement, which can reduce or even eliminate the need for deicing salt usage,” said Jin. “Due to recent changes in the climate causing more extreme weather conditions, we needed to come up with innovative ways to remove ice from roadways.”

Jin and current graduate student Xiaoqiang “Antonio” Ni developed the proprietary formula and tested the limits of the technology for real-world applications.

This self-heating concrete material stores more energy than conventional materials. When the air temperature drops to near freezing temperatures, the material releases that stored energy as heat, making it ideal for clearing ice and removing snow off roads and sidewalks.

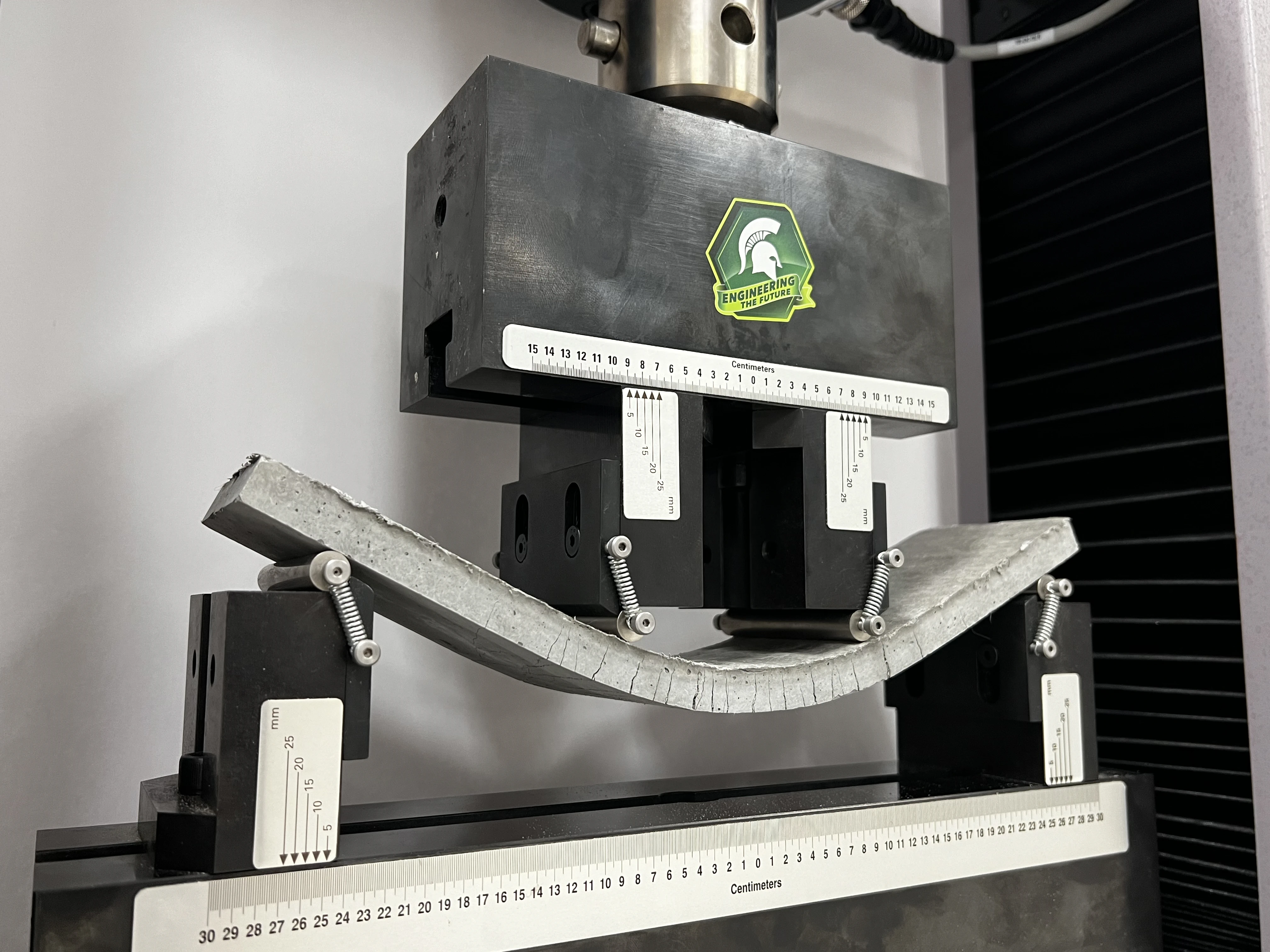

Ni’s testing of the flexibility of the concrete was essential to determining if the material could withstand the weight and stress of heavy automotive traffic.

The team also carefully designed the concrete to effectively heal itself.

“Cracks as thin as a human hair can repair themselves,” said Jin. “It’s like when you have a paper cut on your finger.”

Brennan Sollenberger, a two-time MSU alum in civil engineering who worked in Jin’s lab, supported Ni by helping him prepare samples for testing.

“While working on this project, I was able to see firsthand the snow-melting capabilities of our self-heating concrete mixtures,” said Sollenberger. “We were also able to demonstrate bend-ability and self-healing capabilities.”

This concrete could be a solution that helps people and the environment.

This story was originally published on MSUToday.

About the MSU Innovation Center:

The MSU Innovation Center combines research partnerships, technology transfer, and startup support for MSU faculty who aim to see their research applied to make the world a better place.

Composed of Business Connect, MSU Technologies, and Spartan Innovations, the MSU Innovation Center aims to amplify the impact of faculty research and drive economic growth while positively impacting society to solve real-world challenges with cutting-edge ideas.

Through mutually beneficial, long-term partnerships with the private sector, we connect MSU faculty with companies for corporate-sponsored research collaborations. We also play a key role in facilitating the commercialization and public use of technologies and copyrightable materials, moving MSU’s innovations from the lab to the marketplace. Importantly, we provide significant support for faculty entrepreneurs in establishing startup companies based on technologies developed at MSU.

Is your company interested in a research collaboration with Civil Engineering faculty from MSU? Click Here.